The Metron3D is a HVM ready metrology system for high speed measurement of challenging nanoscale structures which are critical to modern semiconductor manufacturing.

Metron3D combines the well-established benefits of Atomic Force Microscopy (AFM) with fundamentally new inventions that increase throughput by at least 100 times and probe lifetime by 10 times.

The ability to operate at such high speed while maintaining very high accuracy permits chipmakers to benefit from process insensitive 3D surface profiling for in–line metrology and inspection applications for the first time.

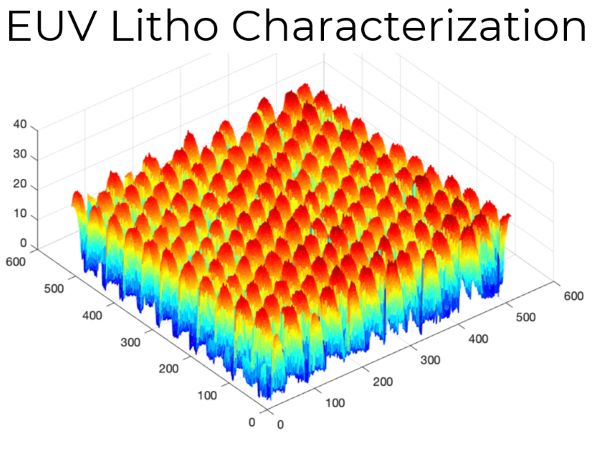

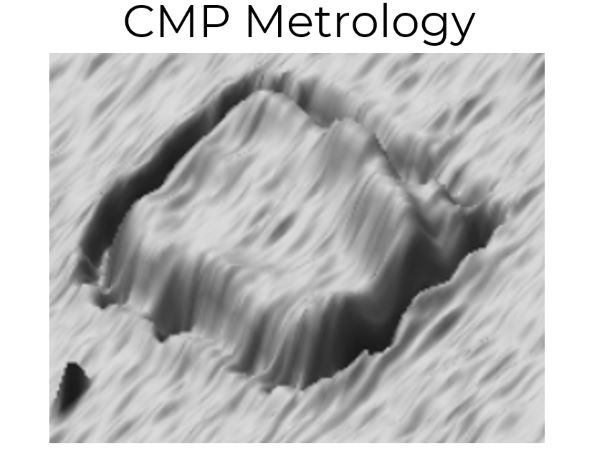

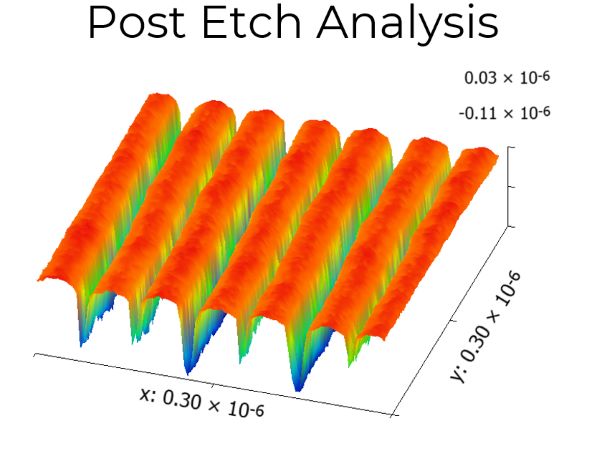

The Metron3D platform enables critical metrology and inspection capabilities that are required to advance semiconductor process control for maximizing yield and lowering wafer costs. As dimensions shrink and device architecture becomes more complex, the Metron3D offers measurement advantages in areas such as CMP performance - both local and long range, EUV Resist characterization and Logic FEOL analysis.

A high capacity on-board probe library with a fully automated probe exchange combined with probe health monitoring and lifetime prediction, enables continuous operation, even in large area measurement tasks such as CMP. An Image Recognition based global alignment system combined with a highly accurate wafer stage, ensures reliable and reproducible capture and measurement of structures of interest.

Key features and specifications

- Throughput of up to 170 WPH for fully automated in-line process control

- Scan area of up to 100 microns square while maintaining high spatial resolution

- Integrated 3-axis interferometry for deep sub-nanometer precision, accuracy and stability

- Proprietary scan mode enabling long probe lifetime for low operating cost

- High capacity probe library with autoloading ensuring seamless operation in HVM