Lithography or ‘Litho’ is the process of transferring the device pattern from a mask (template) into a photo-sensitive film on the wafer called photoresist or simply ‘resist’.

The latest generation of Litho processing, termed EUV, uses a wavelength of 13.5nm which can currently pattern features down to a pitch of 26nm. A future extension of this technology with higher numerical apertures: High NA EUV, will extend this to a pitch of 16nm.

EUV and high NA require a very thin resist layer, which are difficult to image with optical and e-beam metrology techniques, due to limited contrast. In addition, these thin layers are very sensitive to damage and a resulting change in size (shrinkage) when exposed during measurement by these techniques.

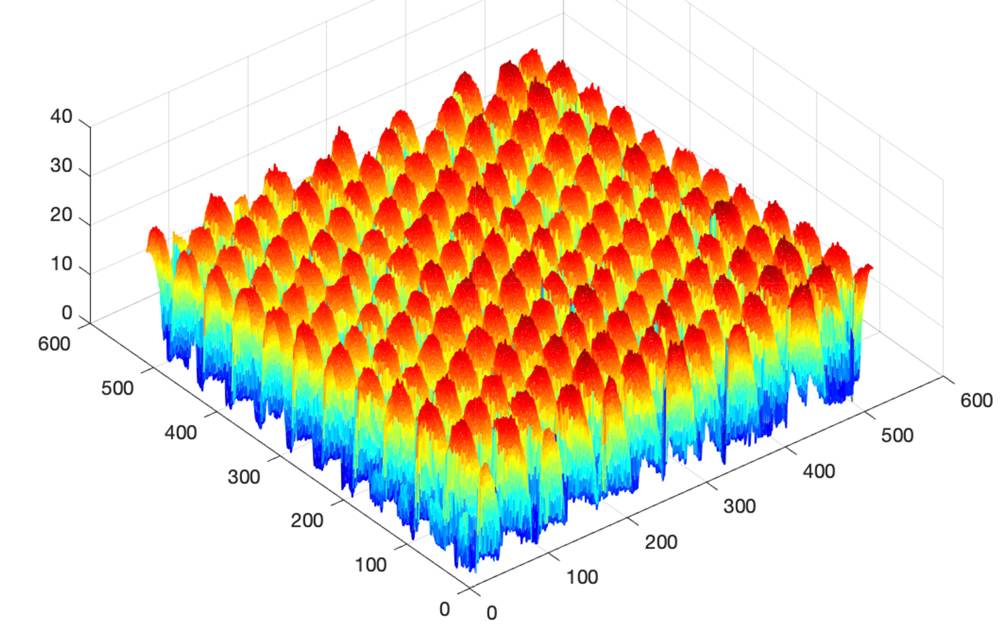

However, the capability to measure EUV patterns is critical. Due to the energy of EUV photons, operation at low exposure doses, and the nature of the resist chemical interactions, EUV Litho processes exhibits a high level of Stochastical variation. Measuring and monitoring this variation is key to controlling the process and yield.

The RPM can measure both the lateral and height of EUV resist within the actual device. This is achieved without damaging the resist and is therefore an ideal solution for EUV litho metrology. Furthermore, the RPM can measure any stochastic variation in the resist pattern and find stochastic defects.